- I.AQL Standard

1.Top Inspection uses widely adopted international standard ANSI/ASQ Z1.4-2003 (equivalent to MIL STD 105E, ISO 2859, NF06-022, BS6001, DIN40080, GB2828) to inspect a randomly selected numbers of products. For consumer product inspection, we focus on each stage of the production: we offer an Initial Production Check (IPC) to ensure the necessary quality of the raw materials and that our client and the vendor understand the specifications. A second process called During Production Inspection (DUPRO) is realized when at least 20% of the run has been completed. The 3rd check is the Final Random Inspection (FRI). This check is proceed when 80% of goods are ready and packed. These processes is defined according to customers’s requirements, ensuring a systematic problems resolution. The final check is Container Loading Supervision (CLS) to make sure the right goods will reach their destination in excellent condition.

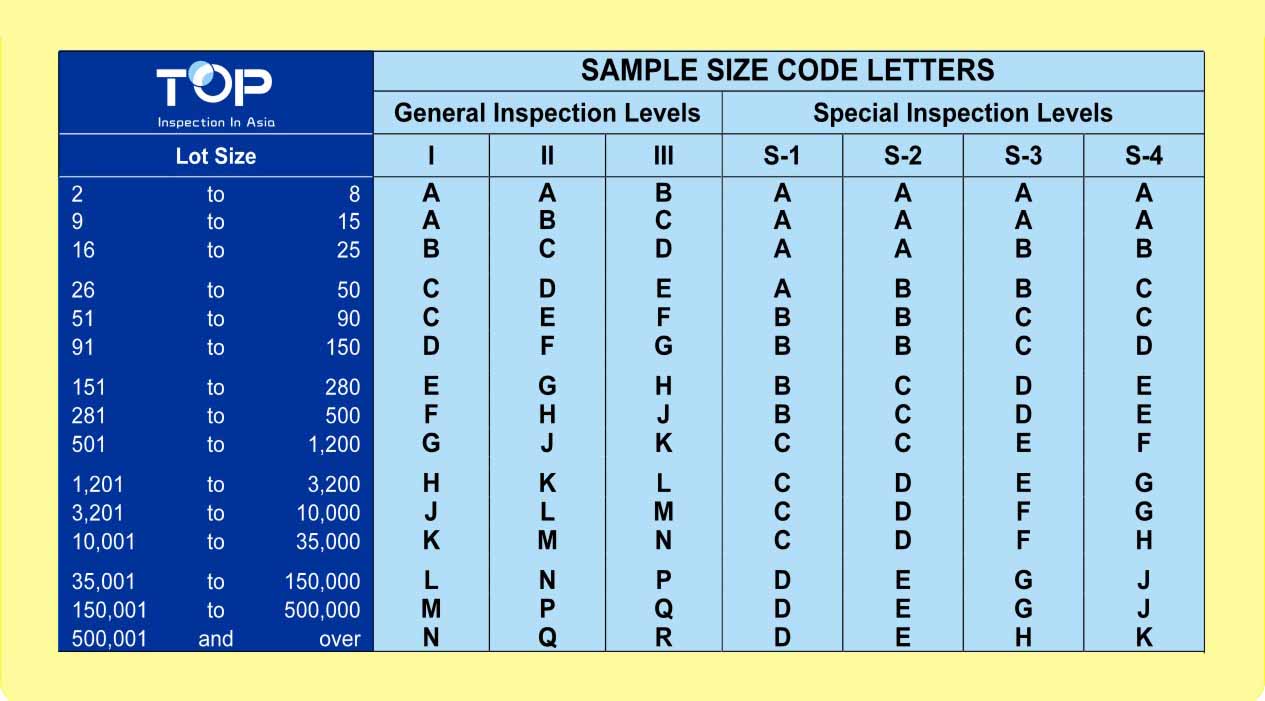

AQL Table(Single sampling plan for normal inspection):

Table A:

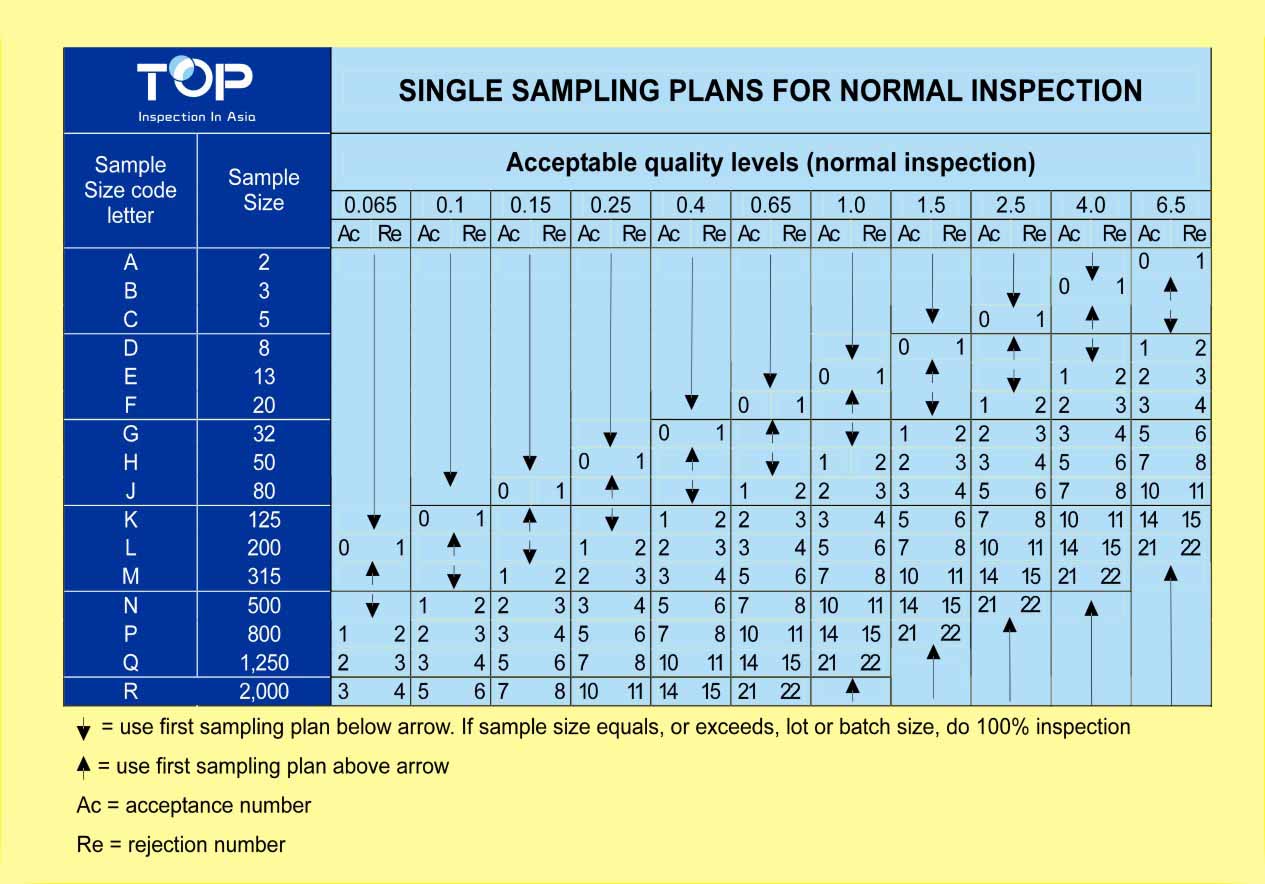

Table B:

As default,Top Inspection uses general inspection level II, Acceptable Quality Level (AQL) Not allowed / 2.5 / 4.0 of Critical, Major, Minor defect.

For example, Consider a shipment of 3,000 units to be inspected. As per single sampling level II, AQL: Not allowed / 2.5 / 4.0 of Critical / Major / Minor:

According to table A, from quantity 1201 to 3200, the corresponding sample size code letter is "K", Then when you check in table B, "K" is corresponding to sample size "125"units.

So the maximum allowed number of defective unit is as follow: Critical Defect 0; Major Defect 7; Minor Defect: 10.

In other words, if the sampling batch of 125 units has more than0 critical defect or 7major defect or more than 10 Minor defects the shipment has to be rejected.

Defect Classifications:

The defect classifications can be specified by client. If not,Top Inspection will define the defects as below:

Critical

Defects that can have hazardous or unsafe consequences for individuals using or maintaining the product. Not following legal regulations will be considered also considered Critical defect.

Major

Function defects which could reduce the usability or solidity of the product as well as obvious visual defects reducing the sale value of the product.

Minor

Defects which are unlikely to reduce the use of the product, but nevertheless may influence the sales.

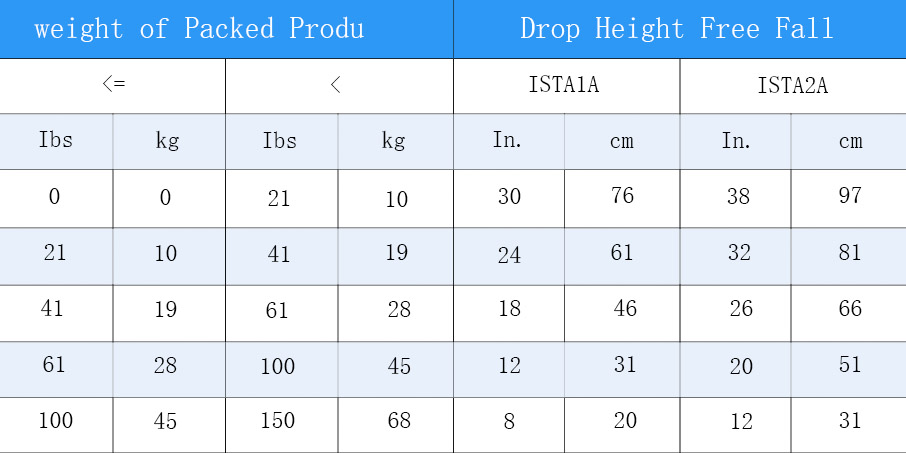

II.International Standard:Carton Drop Test - ISTA1A/2A

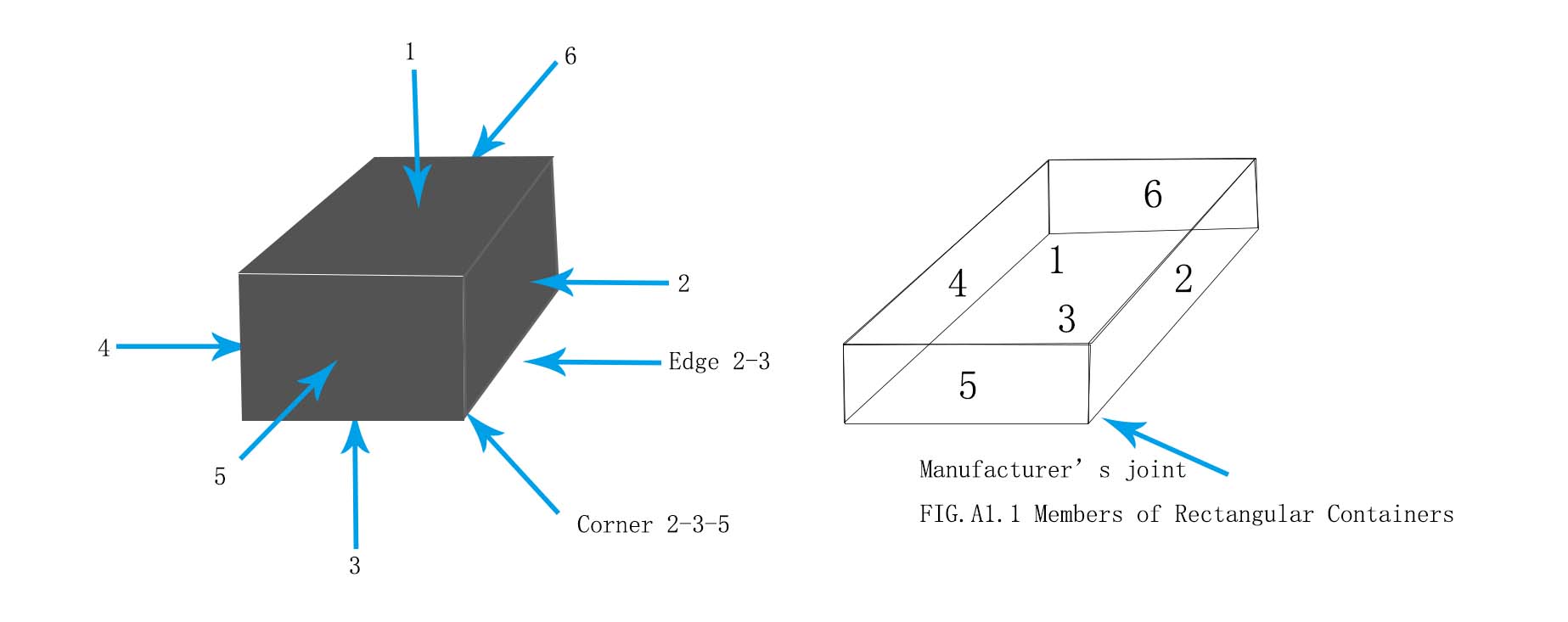

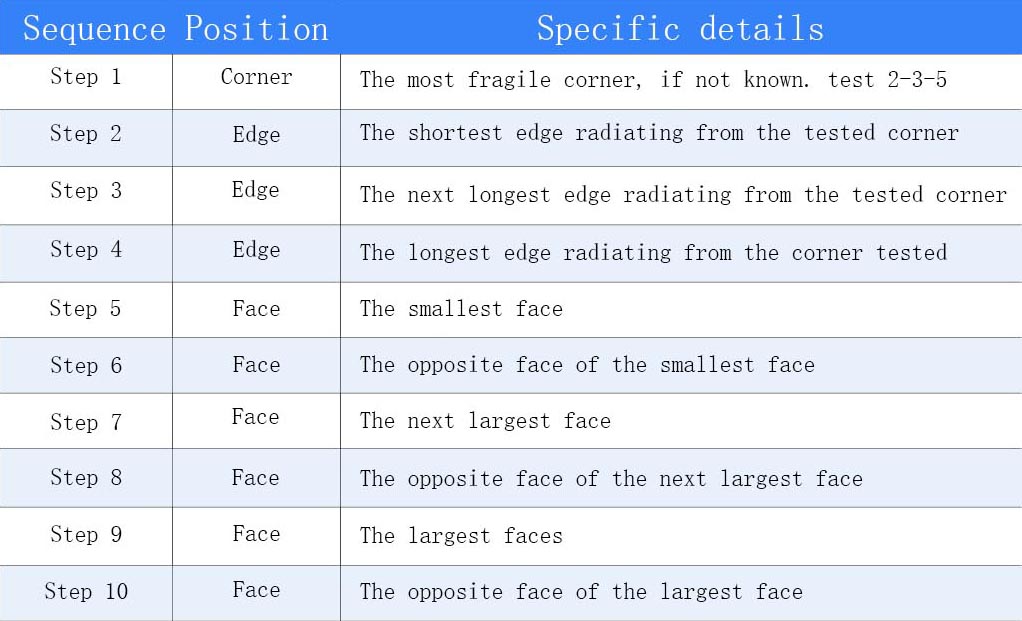

Normally Top Inspection use the carton drop test standard ISTA1A called the method of "one corner three edges six faces of the carton".

1.Drop Height

The drop height varies with the weight of the packed product, Free fall dropping.

2.Drop Procedure

CASE

Top Inspection Operation Center

TOP STANDARDS TECHNICAL SERVICES (SHENZHEN) CO., LTD

Contact Us

Tel: +86 755 26655085, 26655653

Address: Room A 606, Aoshida Building,

Zhongkang Road,Shang Meilin, Futian District,

Shenzhen City, China 518049

Email: sales@topinspection.com